Fill in the form to be notified of product releases

Our expertise

We know a lot about a lot of things, all our teams have extraordinary people skills, and here you’re going to discover our know-how.

01.

Design

Monitoring / Innovation / R&D

Always on the lookout for the latest innovations, the team is constantly on the lookout. From marketing to industrial management, from sales to management, every idea is studied and analysed.

Sementis offers you :

Design / customisation

For 5 years now, we’ve been building a multidisciplinary team and a network of trusted partners. We work with different designers depending on the type and specificity of the products.

The methods office is in constant contact with our partners to transform your ideas into industrial projects. Sementis is constantly on the lookout for new, ever more sustainable materials, both for products and packaging.

The team will always adapt (as far as possible) to your specifications by offering you extensive customisation: a specific handle for the toothbrush, unique laser engraving, marking on the cap of the soap dish, packaging in your colours, etc. Each customer is unique and at Sementis, you are at the heart of the process.

02.

Manufacturing

Prototyping

The next stage after design is prototyping, and what could be better than being able to touch a product to see for yourself its design, shape and size? To do this, we equipped ourselves with a 3D printer.

We also have a team of partners to take over for more specific products or even more realistic renderings.

Manufacturing / Production

Once the famous Cost/Quality/Delivery triptych has been decided, it’s time to give industrial reality to everything we’ve been able to imagine with you and your project teams…

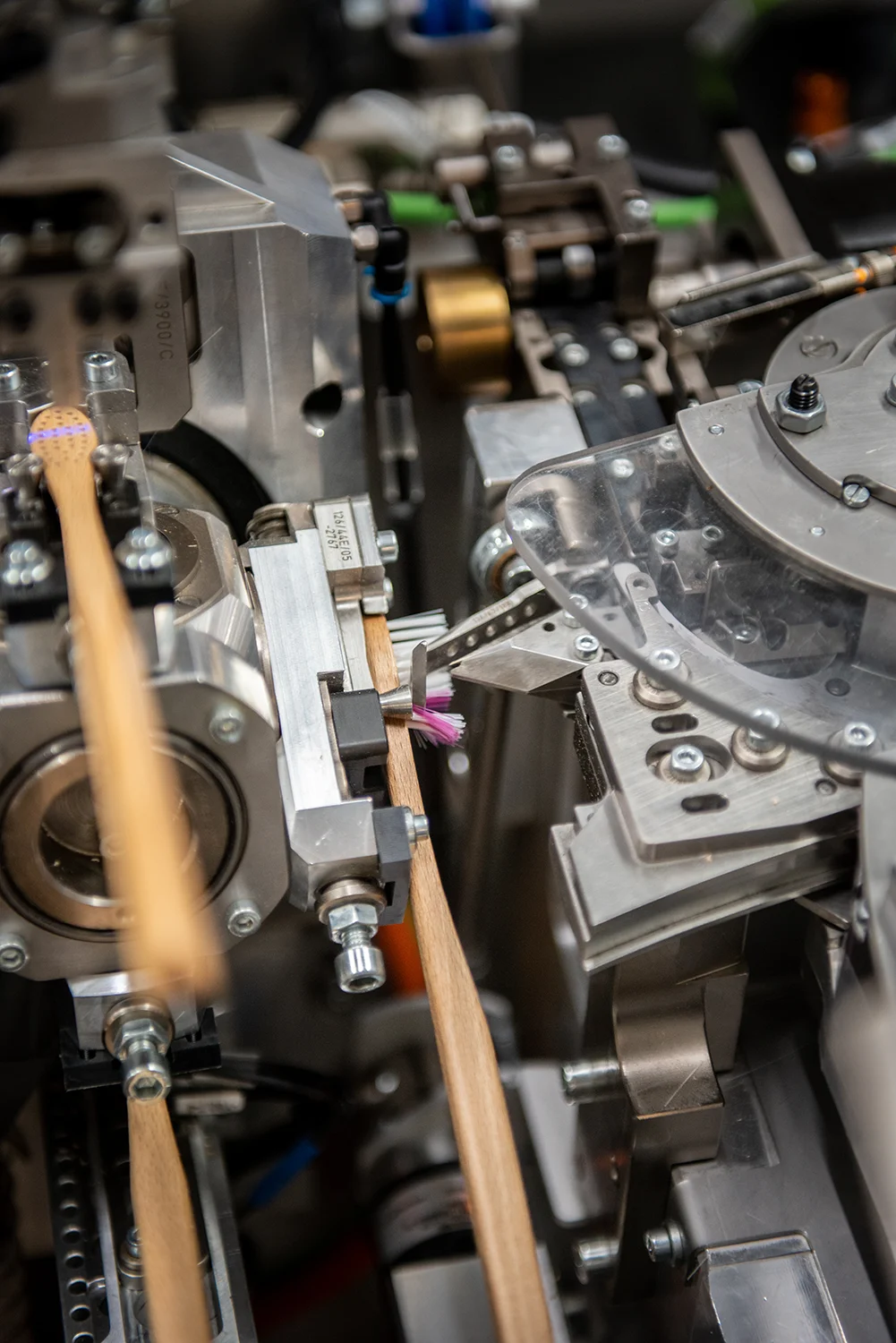

If it’s a toothbrush project, whether with or without an interchangeable head, in wood or another bio-sourced or recycled material, it’s at our factory in Plessis-Grammoire that the future object will come to life and be produced as a finished product.

If your project involves another object, we’ll act as the orchestra conductor and monitor the project from A to Z, as if it were being manufactured in our factory.

03.

Quality

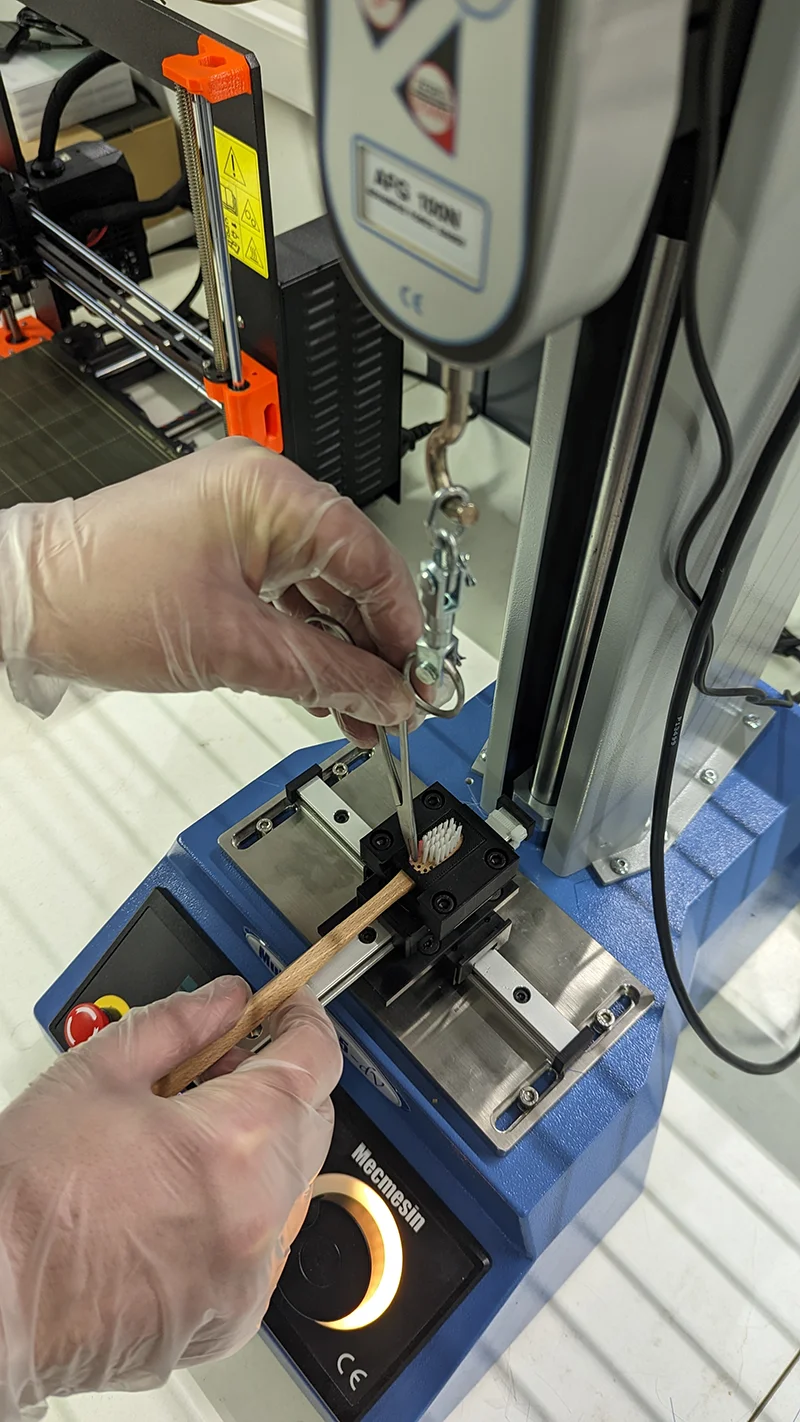

Controls throughout your project

Our constant concern is to deliver a product and service that meet your expectations.

At the start of production, we draw up a schedule of checks to be carried out throughout the production process.

Every input is scrupulously checked and screened against our quality control grid.

During the process, we take samples and carry out the necessary checks.

Finally, a final inspection at the end of production provides the reassurance needed to ensure that the life cycle of the finished product runs smoothly.

04.

Logistics

Packaging

We can offer a complete service from design to storage of finished products. We work with two partners, Entreprises Adaptées, who carry out the packaging, boxing and quality control on our behalf.

We don’t use any virgin plastic-based packaging and keep the production of unnecessary waste to a minimum. So, even if we’re working with a hygiene product, it’s not always necessary to multiply the protective packaging.

Most of our packaging, whether primary or secondary, is made from recycled paper and cardboard.

Order preparation

And last but not least: logistics! Delivering the right products at the right time to the right place in the right condition is an integral part of the positive experience we want you to enjoy.

That’s why we make it a point of honour to work as flexibly as possible so that we can respond quickly. Depending on the volumes required, we offer this service either directly from our factory in Le Plessis-Grammoire, or via our network of trusted partners, all located within a few kilometres of our factory to minimise the carbon impact of the customer order.

05.

Recycling

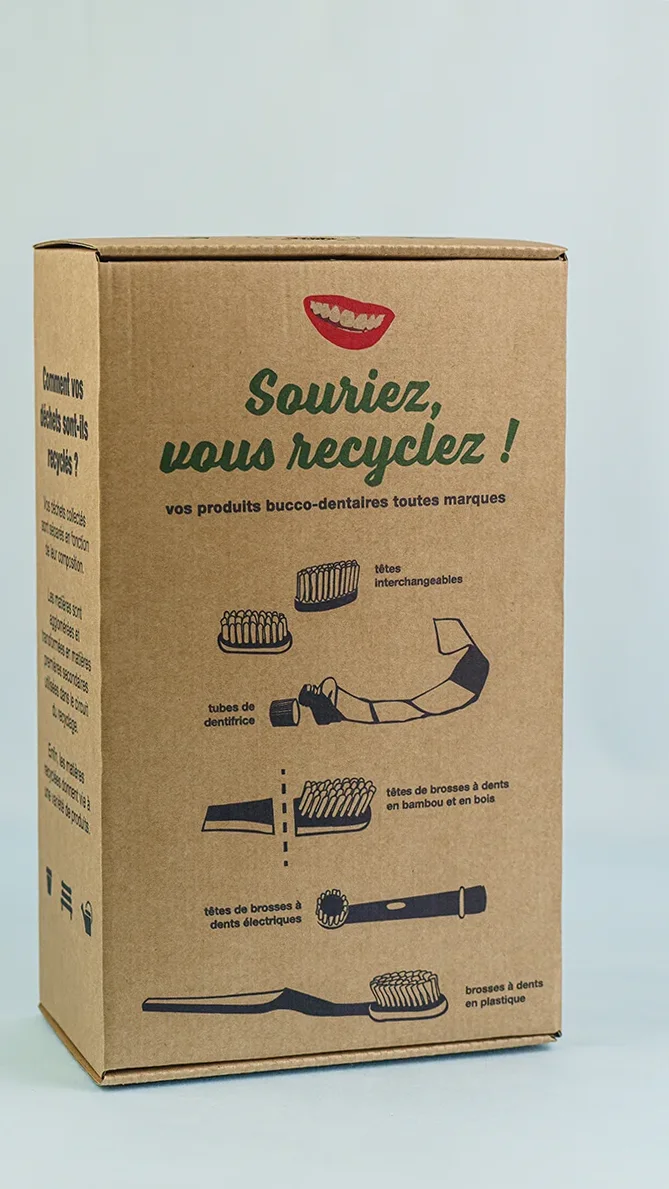

End-of-life product management

The best waste is the waste we don’t produce.

This adage often guides us in our daily lives, and it’s what led us to develop our toothbrush with interchangeable head (which reduces the use of plastic in toothbrushing by over 90%).

Our distributor business also has an oral waste recycling programme. We can consider making this oral waste collection programme available to you.

In addition, we try as far as possible to reuse products that do not comply with the production process (machine jams, rejects due to product defects, etc.). We can also donate certain products that do not meet our quality criteria to charities (e.g. Unisoap, Toit à Moi, etc.).